Use of Nonwovens as Geotextiles (Educational Research)

Submitted by: Terezie Zapletalova and Rongguo Zaho

Introduction

Nonwoven geotextiles are widely used for the functions of separation, reinforcement, drainage, erosion control, and moisture barrier. Geotextiles are an very important part of the whole nonwoven industry. The total North American geotextile market was estimated at over 420 million square yards in 1994. Approximately 115 million square yards are used as separation / stabilization geotextiles, about 105 million square yards are used as paving fabrics [1]. China is a big market for geotextiles. According to Wang [2], 60-80 million square meter geotextiles will be required for 5000 projects before year 2000. These projects include highway construction, airport construction, water conservation and soil erosion protection [2]. Some important applications are described as follows:

- Separation: fabrics are used to separate two dissimilar

materials.

- Reinforcement: fabrics reduce the level of stress in the

foundation soil due to horizontal shear stresses mobilized by vertical

loads. This application spreads the load over a large area and thereby

decreases its intensity. That is the unit vertical stress is reduced and

means less likelihood of failure.

- Drainage: The second largest area of current fabric

utilization since the permeability of the fabric can be controlled.

- Erosion control: fabric acts as both a separator and as a

drainage layer, but when its primary function is to aid in erosion

control it is placed in this special category.

- Moisture barrier: The hydrophobic nature of some of the

olefin Fibers can be exploited to prevent the moisture in seeping

through and disturbing fine soil structure.

Apart from these fabric materials can act as forms to be filled with other materials and thereby conform to the shapes and topography of any surface on which they are constructed. The impermeable fabrics coated with vinyl, polyurethane etc. act like air- supported structures (inflated floodgates in tidal zones).

fiber/ fabric Types From the raw material viewpoint,

approximately

of geotextiles are made from polypropylene (PP); the

remainder are from polyester , other polymers and natural Fibers [1]. Low

cost, low specific gravity and strength properties make PP the predominant

raw material in the field of geotextiles. Some of he nonwoven fabrics,

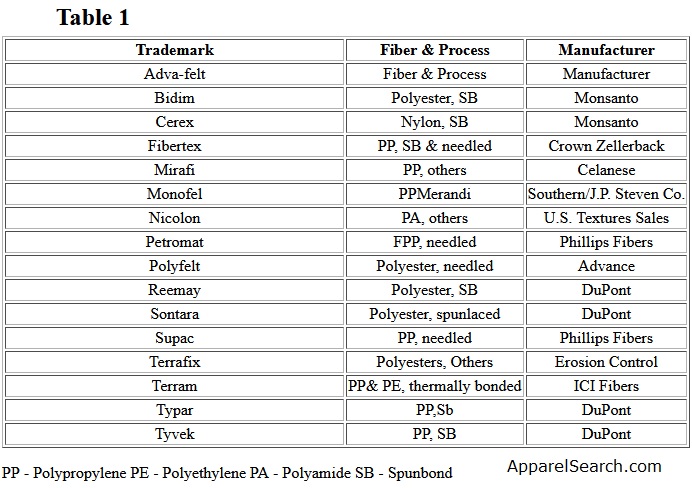

their trademarks and manufacturers are given below:

Table 1

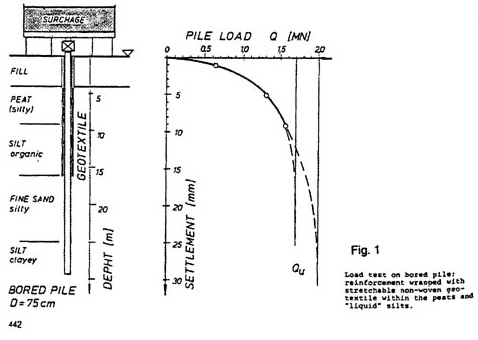

Separation Function and Bearing Capacity of Nonwovens Pile Foundation In peats and silts of a soft plastic to liquid consistency, constriction or uncontrolled flow out to the sides of the fresh concrete into the soil has to be avoided. This can be achieved by wrapping a stretchable nonwoven fabric around the reinforcement cage. The hydraulic pressure of the new concrete presses the nonwoven fabric outward, when the pipe is removed, thus guaranteeing sufficient cover over the steel ( Fig.1).

Figure 1

Vertical Drains Vertical drains accelerate primary consolidation of soft, highly saturated soils. As they do not improve secondary creeping, they are hardly suitable for peats but work well for weak clays, silts and organically contaminated soils. Among the various techniques the nonwoven fabrics drains developed in Austria represent an innovation. They look like long hoses being filled with sand and lowered into vertical holes. The usual diameter is 10 cm; the width of the grid is approximately 2-4 m, according to the kind of soil. As filter sand, a grain size of 2-7 mm is preferred.

Sewer Pipes Pipes bedded into the subsoil can withstand stresses of static and dynamic load better, if geotextiles are incorporated. Most unfavorable conditions occur (maximum bending points of the pipe) if the pipe is not supported on the sides but only rests on a linear line. In soft and inhomogeneous subsoil, there is the additional danger of the pipe resting on uneven and yielding ground, which can cause localized excessive stresses, especially in the connection sockets.

If a nonwoven fabric is laid onto the subsoil, the base on the pipe trench can be covered with sandy gravel that can be sufficiently compacted. Thus the bearing capacity of the pipe is increased considerably and differential settlements reduced.

Metal Culverts These flexible structures are able to absorb very high radial pressures without any significant deformation, if the all surrounding-embedding is carefully compacted (Fig. 2). If the subsoil conditions are poor, nonwoven fabrics can be used instead. These geotextiles enable a sufficient compaction of the base bedding and good drainage of the water saturated subsoil during consolidation. The advantages of using flexible culverts are lower cost, shorter construction period and reduced differential settlements between embankments and culvert.

Figure 2 - sorry, image no longer available.

The great deformability of flexible pipes and culverts is of advantage for heterogeneous soil conditions and especially for embankments on soft subsoil. In such a case the culvert is placed upon a thin replaced layer (on geotextiles) ahead of filling the dam (Fig.3).

Figure 3 - sorry, image no longer available.

Railway construction Due to heavy dynamic load resulting from train traffic, the stony ballast is very often contaminated by rising fine particles from the underlying soil. This "pumping up" not only leads to a deformation of the ground, but also to a greater susceptibility to freezing and thawing (in the ballast). This eventually causes a gradual decrease in the bearing capacity of the upper structure. Graduated sandy-gravel filters and synthetic nonwovens can be used as separating layers. The use of separation and stabilization geotextiles keeps the subgrade soil from pumping-up into the aggregate that support the pavement or unpaved aggregate surface. Rigid soil stabilizers (cement, lime etc.) can not provide long-term stabilization. There is also uncertainty about the long-term effectiveness of bituminous sealing of the track bed.

Nonwoven fabrics with a low stretch property should always be covered with a thin layer of coarse sands in order to prevent perforation by the sharp stones of the ballast. This danger exists during lying (particularly with tamping machines), when the subsoil is inhomogeneous. It also exists later on through dynamic loading. Finally, the coarse sand should protect the nonwoven fabric against damage caused by the chains of the machines, which clean the ballast track bed.

Long-term observations have shown that neither staple fiber nor thin rigid nonwovens are suitable, for railway construction. Staple fiber nonwoven shows material fatigue (chemical bonding) and thin rigid nonwovens because of mechanical damage. It is found that the geotextiles made of endless long fiber that are mechanically bonded generally fulfill the expectations.

Environmental Applications

Nonwoven geotextiles play a major role in engineered systems designed to achieve the stricter waste disposal and emissions control regulations that improved over the past two decades. Both liner and cover systems are layered systems that include hydraulic barriers and liquid/ gas collection systems. Cross-sections of the liner and cover systems that are commonly used in both hazardous and municipal solid waste landfill are shown on Fig 5. Geotextiles can be used in landfill systems to provide the following functions:

- Filtration: the liquid collection systems must be protected against

clogging caused by soil or waste particles carried by the liquids.

- Protection: The barrier systems include a thin geomembrane that must

be protected from puncture.

- Bio-barrier: Impregnated with a biocide agent, geotextiles are being

used to limit root penetration into the landfill system.

- Barrier: Geosynthetic clay liners (GCLs) use geotextiles to confirm

bentonite granules into sheets that can be used to form liners.

Filtration Collector/drain systems in the covers beneath the waste must be designed to handle waters that may have high total dissolved solids (TDS). Additionally, it may be a very open system that must perform its role adjacent to layers of waste or soil. The geotextile must then provide an opening size that will allow the liquid to enter the collector system while retaining waste or soil particles. This filter layer can be constructed using a geotextile or a graded soil filter. Both the filter and the geotextile must be designed to provide adequate flow capacity and soil retention to resist clogging. Graded filters are commonly used of several layers of sands of different grades (fine to coarse) and are several feet thick. Geotextiles serve the same function as them at reduced cost and space.

In general, most geotextiles have permittivity values adequate for landfill applications. The geotextile filter design determines the opening size required to retain the soil of waste particles upstream of the geotextile. The 95% opening size (O95) of the geotextile (ASTM D4751), is related to the particles retained through the following type of relationship

O95 = (d50, CU, DR)

Where d50 is the 50% size of the upstream particles, CU is the uniformity of the particle size; DR is the relative density of upstream particles. An increase in the hydraulic flow gradient across the geotextile or a significant reduction in flow rate affects degree of clogging the geotextile.

Nonwoven materials are vulnerable to clogging and biological growth, which can reduce the effective permittivity of the geotextile 20 fold (Fig 6). Because of this, some European countries and US designers have stopped using geotextile filters between the waste and leachate collection system. All geotextiles and nonwovens in particular resist efforts to back wash particles out of he fabric.

Figure 6 - sorry, image no longer available.

Protection Both covers and liners of waste containment systems rely on a barrier system composed of several feet of compacted soil covered by a thin geomembrane. The geomembrane is commonly a 60-mil HDPE or 40-mil PVC field seamed system. This thin membrane must be protected from puncture both during construction and after the facility is placed in service. The ability of a geotextile to protect the geomembrane from puncture is more a function of its basis weight than its physical strength and thickness.

Bio-barrier The geotextile in the cover sections exposed to root growth from plants require prevention of cover soil erosion. Such penetration remains the most critical challenge to the long-term integrity of cover systems. The product has a limited life expectancy. It is a function of moisture in the contact soil and also it is quite expensive.

Barriers Geosynthetic clay liners (GCLs) were developed to waterproof building basements and for lining of landscaping ponds. GCLs are made by bonding bentonite granules between layers of geotextiles. The bonding can be performed by sandwiching the bentonite between two nonwovens and then needling the layers or by the use of water-based adhesive to bond bentonite between the two geotextiles.

Two problems associated with these kinds of fabrics limit the application of these materials to landfill slopes:

- The geotextile surface has a low coefficient of friction when placed

against the geomembranes

- As the bentonite hydrates, the strength of bentonite decreases and

the GCL may act as a plane of weakness

Hence, improved methods of needling or sewing the two geotextiles that form the GCL together must be developed.

References:

- Mark L. Marienfeld " Geotextiletrends and developments" Tappi

Journal 78 (9) : 143-146 (1995)

- Wang Xiang-nong " Annual Textile Meeting Held In China" Nonwoven

Industry, March : 41 (1997)

- Koerner, Welsh: Construction and Geotechnical Engineering Using

Synthetic fabrics, John Wiley & Sons Ltd., 1980

- Second International Conference on Geotextiles, vol.II, August

1-6th, Las Vegas, p441

- IDEA'92, Book of papers

Visit our nonwoven education page.

Apparel Search

Add Your Company Contact

Us About Us Advertise

News Letter Legal

Help

Copyright ©

1999-2023 Apparel Search Company.

All Rights Reserved.

Buy Fashion

For The Holidays.