HYG-5544-01

Joyce Smith, Ph.D.

Norma Pitts

Socks, Socks, Socks

Buying socks may appear simple, but some day while shopping, just stop and look at the variety. Dozens of types of socks exist. Many are interchangeable in terms of quality and appearance. Others are designed to meet specific needs. So let's take a closer look at socks, so purchases can match the needs of individual wearers and their activities.

fiber Content

Socks come in a variety of fibers and fiber combinations. Commonly used fibers include cotton, wool, nylon, acrylic, polyester, olefin, and spandex. Occasionally, luxury fibers such as silk, linen, cashmere, or mohair will be blended for softness, but this adds to the cost.

Natural fibers are absorbent. The presence of cotton and wool helps

absorb perspiration. Wool absorbs up to 30% of its weight in moisture before

feeling "wet," making it a desirable choice in winter

but once the fabric

becomes saturated and moist, it feels cold to the wearer.

The term "Natural Blend Cotton" is used on the label of many socks. These socks have a high content of cotton (60%) with smaller amounts of synthetics, usually nylon or spandex, for reinforcement or support. Occasionally, linen, a natural fiber, is knitted into the toe of socks for reinforcement. Linen is a relatively strong fiber and adds durability as well as absorbency and comfort. Silk socks are usually quite smooth and absorbent. They make a good layer next to the skin, but are not very durable.

Synthetic fibers, particularly nylon, are strong and make an excellent choice for socks which commonly receive hard wear. Besides durability, synthetic fibers add shrink resistance. Socks may be 100% nylon or reinforced at the toe and heel with this durable fiber.

Acrylic fibers are long wearing but also add a cushiony softness and bulk to socks made from them. Acrylic fibers are commonly found in socks for casual wear. Olefin fiber has become important for outdoor sport socks. Olefin fibers do not absorb moisture; however, both olefin and acrylic have wicking ability. This means that moisture travels along the fiber away from the skin. Acrylic and olefin socks are often worn next to the skin, with a wool or cotton sock over them to absorb moisture. Some blends of socks are made so the fibers with wicking ability are next to the skin and the absorbent fiber forms an outer layer. This accomplishes the same result as wearing two socks, but is less bulky.

Stretch fibers, including spandex, elastic or rubber, are present in many socks. They help socks stay up and hug the leg and foot. Spandex is used extensively to provide support in the ankle, calf, and arch areas, especially in sport socks. These socks stay in place and increase blood circulation. While elastic or rubber yarns sometimes are used, they deteriorate from body oils and do not last as long as spandex stretch yarns. Also, elastic in sock tops binds more than spandex.

Construction

Socks are knitted, giving them stretch and the ability to conform to the foot and leg. Generally, a stockinette or plain knit stitch is used in the foot area and a rib stitch is used in the leg area (though some socks are made totally of rib stitch). The rib stitch is very stretchy, with the ability to return to shape. As both the stockinette and rib stitches are simple knit constructions, the stitch can ravel out if a yarn is broken. Look carefully at socks for loose threads, broken yarns, or holes that could start to run or ravel with wear. Also, look for evenly knitted stitches on socks and a flat seam at the toe. Toe seams placed high over the toe are usually more comfortable than those at the end of the toe. Both the toe and heel areas should be smooth, otherwise irritation could occur during wear.

Stockinette |

Rib Stitch |

Tube sock |

Tube socks are circular knits and have no shaped heel area. The socks can be put on several ways and will stretch enough on any side to fit the heel area. Sometimes the tube sock has one seam at the end of the toe. Be certain this is very flat and smooth as it is in a critical area for wearing comfort.

Check also the ribbing at the top of the sock. Socks that keep falling down are annoying. Spandex yarns in the calf area will help prevent this. Generally, the wider the band of ribbing, the better the sock will stay up. Also, a narrow band of stretch yarn (often made of elastic) tends to roll over or curl at the top, causing discomfort to the wearer.

Heel shape in a sock is equally important to comfort. A square heel gives the best fit. A small, curved heel tends to slip under the foot easily and bunch in the shoe.

Another feature of construction to check is the amount of stretch in the sock. Be certain both the body and the ankle areas of the sock will slide over the foot easily. People with high insteps especially need to check this.

Toe and heel reinforcements are important features. Nylon thread is often knitted into these areas to prolong wear. Occasionally, linen yarns are knitted into the toe area for the same purpose. While linen is a strong fiber, it does not equal the durability of nylon reinforcements. In any case, four- or six-ply yarns should be used in these areas. They form thicker yarns which give longer wear.

The reinforcement should be wide enough to cover all joints on the toes.

This area may be double knit for increased durability. Check for an extra

high heel guard or reinforcement above the location where the back of the

shoe rubs against the sock. On adult men's socks, this will be 3

3 1/2" from

the bottom of the sock.

Concerning general construction, some socks feature cotton lisle yarns. These yarns are made from high quality, long staple cotton ply yarns. The amount of twist on these yarns is specified by Federal Trade Commission regulations. The combination of twist with heavier-ply yarns gives durability, while the soft, good quality cotton yarns add strength and comfort. Usually, socks from cotton lisle are made into plain- or stockinette-stitch socks.

One final but important point to consider is the decoration of socks. This can be knitted in or applied. Patterns knitted in, especially those involving contrasting colors, should be sharp and clear. Poorly made socks will have uneven borders and overlapping stripes in the body of the sock. Look for loose threads with knitted designs. Threads can pull out and cause raveling. Loose threads can also form loops and catch toes. Applied designs should be smooth, secure, and non-irritating to the skin. Applied designs which are stamped or painted on are less durable. The color may crack and flake off over time. Decorations like buttons, bells, lace and bows can be sewn on. These need to be sewn on securely, but over time, may not hold up.

Finishes

Few finishes are applied to socks. However, those that are perform important functions. Anti-static finishes are desirable on socks made from synthetic fibers. They help prevent trousers from clinging to the socks and lint from collecting on them during wear and laundering.

A more common finish for socks is one that resists the buildup of odor and bacteria. The feet are among the three areas of the body that contain large sweat glands (the other two are the armpits and the palms of the hands). Feet wrapped in a layer of socks and shoes for long periods become warm and perspire. Although perspiration is odorless and 99% water, it provides a perfect medium for bacteria to grow. The bacteria cause foot odor. Anti-bacterial agents in the fiber reduce bacteria growth and resulting odor. Most anti-bacterial finishes used today are durable and remain after repeated launderings.

New Technology and Performance fabrics

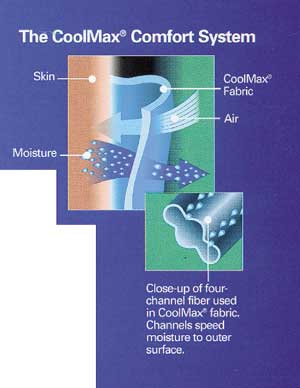

Special engineered polyester fibers have been developed for specific

sports activities. For warmer weather, Dupont developed Coolmax

fabric. The fiber cross-section looks like a double scallop shape which

gives the fiber 20% more surface area than regular fibers. This allows water

to spread over a greater area in the fabric, so it can evaporate faster. The

fiber enhances comfort and breathability by wicking away moisture so it can

evaporate (Figure 1). Coolmax

claims to possess superior wicking

and evaporation of perspiration moisture.

Coolmax

is just one brand-name in the growing category of

high-technology wicking fabrics. Other brand names in this market include

Dryline, Dryfit, Dryskin, Powerdry, Hydrofil, Capeline, BiPolar and Stretch

Supplex.

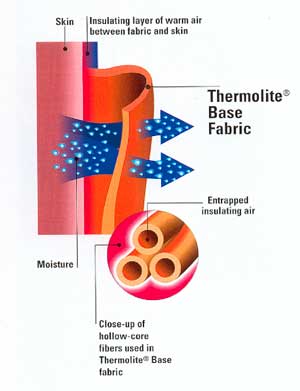

For colder weather, fabrics like Thermolite

contain hollow

core fibers with a convoluted or twisted surface. The hollow center holds

air, resulting in additional thermal insulation as well as a 20% reduction

in fiber weight and space which enables freedom of movement. The surface and

convolutions enhance wicking properties (Figure 2). Additional crimp in the

fibers creates bulk which traps air. This fiber is designed for use in

thermal underwear, gloves, socks, and turtleneck T-shirts.

Other new technologies include the development of socks which reduce

abrasion. Blisters form through abrasion or rubbing of the foot, usually

toes, against the sock and shoe. Breeze

socks are designed so

there is greater abrasion between the sock and foot than between the sock

and shoe. The sock then sticks to the foot, but slides against the shoe and

protects the foot. The result is less abrasion and fewer blisters.

| Figure 1. Close-up of four-channel

fiber.

|

Figure 2.

|

Types

For men, four major types of socks exist

dress, casual, sport and work.

Dress socks may be worn with business suits during the day or for special

occasions. Usually, they are a flat, lightweight knit and may even have

sheer panels, especially for warm-weather use. They come in calf and

over-calf lengths.

Casual socks are worn with sports wear and in less formal situations. They are made from bulky yarns, usually wool or acrylic, or from cotton for softness and comfort. They may be blended with nylon or spandex for improved fit and durability, or olefin for comfort to wick away moisture. Casual socks, regardless of construction, normally are calf length.

Support socks have become more popular and acceptable in recent years. Generally, in men's socks they are in over-the-calf lengths. Support socks contain higher percentages of spandex to help support muscles and relieve fatigue and strain.

Work socks are designed for durability and hard wear. They use cotton fiber for absorbency and often feature nylon reinforcement in the heel and toe. Winter work socks will have wool or acrylic yarns for warmth. Traditionally, work socks have been white or natural colors, but steel blue, darker colors, and "ragg" wool socks with dark and light flecks are available now.

Socks for women are usually for casual or sports activities. They may be ankle length, calf length (crew), or knee length. Bulky yarns in wool or acrylic fibers are most common. They often have knitted-in designs in one or more contrasting colors, but lightweight nylon knits are also available and become more fashionable at times.

Trouser socks are choices available for women. These are knee high and are designed to be worn with slacks. Trouser socks may be tube style or shaped in the heel, and frequently feature either subtle or brightly colored knitted-in motifs. Trouser socks are usually nylon and are similar to heavier weight or opaque panty hose or tights. As with nylon stockings, they can and do get runs.

As emphasis on physical fitness has increased for both men and women, so have the types of socks designed for active sports. Spandex panels and ribbed construction through the ankle, arch and calf offer support to these areas during active periods. Also, the panels hold socks in place so they do not slide down and cause discomfort. Cushioned soles constructed from stretch terry pile lining reduce shock and resist abrasion. Reinforced toe and heel areas provide durability. Toe seams are placed high on the toe for additional comfort.

Many sport socks feature a stretch terry knit stitch with looped terry throughout the sock or in selected locations. Increasingly, terry is placed on the outside and smooth knit construction next to the foot. This construction reduces rubbing and so reduces blisters and callouses.

Socks made with stitched terry yarn provide more cushion and comfort to the wearer. Tennis and racquetball players need cushioning at the ball, heel and toe areas to absorb shock, but also at the arch and over the toes to protect the feet during heavy, fast, quick movements. Runners also need cushioning at the ball, heel and toes to reduce shock abrasion and blisters; however, a flat knit over the instep and less bulk overall is best for socks used with this sport. Basketball players usually prefer high, cushioned socks to protect feet and legs, but also need socks which will stay up during play. Cyclists, on the other hand, prefer thin, lightweight socks so they can feel the pedals and experience more agile movement. When special socks are needed, they should be worn when buying sports shoes, since these socks can affect the fit of the shoe.

Another concern for individuals involved in active sports such as tennis, running, basketball, and to a lesser extent, walking, is perspiration. Socks with wicking action or absorbency help keep feet dry. This reduces the potential for foot odor and athlete's foot. Both acrylic and olefin fibers feature wicking action that carries moisture away from the skin to an outside absorbent layer. Also, wool absorbs 30% of its weight in moisture without feeling moist. The presence of these fibers helps control moisture and increases comfort for the wearer.

Some individuals prefer short or quarter top socks that cover only the foot area, especially for warm weather activities. These socks often feature similar sport specific cushioning available in the standard length socks mentioned above. Some short styles have a tendency to slip down into the back of the shoe. Look for construction features such as pompons at the back heel, knit ribbing or an edge roll over the heel to counteract this problem.

Thermal socks are good choices for outdoor sportswear. Individuals who ski, hunt, or work outside during cold weather will find that these socks keep the feet and toes quite warm. Thermal socks may be a textured knit featuring tiny air pockets in a waffle or popcorn design. These air pockets trap body heat to provide insulation and warmth. Neoprene socks feature a microporous core to seal in heat and keep feet dry, yet prevent perspiration build up through the breathable structure.

The stretch terry knit in the foot area of some casual socks provides insulative properties. Also, socks made from bulky yarns that include wool and acrylic will do the same thing but to a lesser degree. Cold-weather protection can also be achieved by wearing a combination of olefin socks next to the skin and bulky, more absorbent socks over them. The wicking ability of olefin carries moisture away from the foot to the more absorbent outer layer.

One last specialty sock is the boot sock. These extra-high socks extend beyond the tops of hunting, work, and western-style boots. They usually contain some wool and nylon and may be blended with other fibers to meet specific needs.

Knee-length sportsock

|

Crew sock

|

Anklet

|

Quarter top

|

Care

Laundering of socks requires few special precautions other than concern for color. As colors used in socks may run during laundering, wash with other dark colored items. Also, wash in warm, not hot, water to reduce color bleeding.

Always check labels for colorfastness. This is especially important with white sport socks that feature colorful stripes or designs. Colors may run into the white area if dyes are not colorfast or if water temperatures are too hot.

Finally, avoid using chlorine bleach when washing socks containing wool, silk, spandex, or elastic. Chlorine bleach will damage these fibers.

Also, check the care label of socks containing wool and/or olefin. Most wool or wool/blend socks can be machine washed and dryer dried, but some may specify hand washing. Socks made from 100% olefin should be air dried, since this fiber is very heat sensitive; however, socks containing blends of olefin with other fibers can usually be dryer dried at low temperatures.

Reference

Gulbrandson, Ruth (1992). Buying Socks. Fargo, ND: North Dakota Cooperative Extension Service.

Citation

Coolmax

and Thermolite

graphics provided by

Dupont Dacron

Barley Mill Plaza

P.O. Box 80022

Wilmington, DE 19880-0022

1983

Revised 3/01

Apparel Search

Add Your Company

Contact

Us About Us

Advertise

News Letter

Legal

Help

Copyright © 1999-2023 Apparel Search Company.

All Rights Reserved.